Winter in the Algarve: the walls are damp, mould is forming and the evaporative cold increases heating costs. We won’t go into detail here about the serious threat to health posed by damp and mould.

What do we do?

First of all we find out the cause of the moisture:

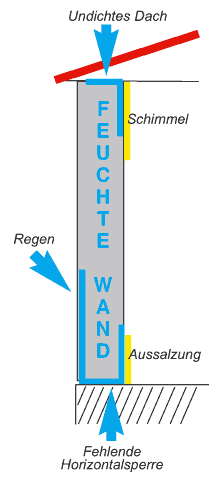

- Is it coming from above through a leaky roof?

- … or from the outside through bad painting, fine hairline cracks in the plaster?

- … or from below due to a lack of a horizontal barrier in the masonry?

- … or does it have other possible causes?

To determine the cause of the problem, we use state-of-the-art measuring equipment and procedures.

After the situation analysis, we are able to deal with the moisture in the building in a targeted manner, using the appropriate measures and materials.

We use only high quality and proven products. Only in this way can we ensure that the problem will not reocur in the future.

Trust our experience – we will be happy to advise you.

Our Solutions

Installation of a subsequent horizontal barrier

The cause

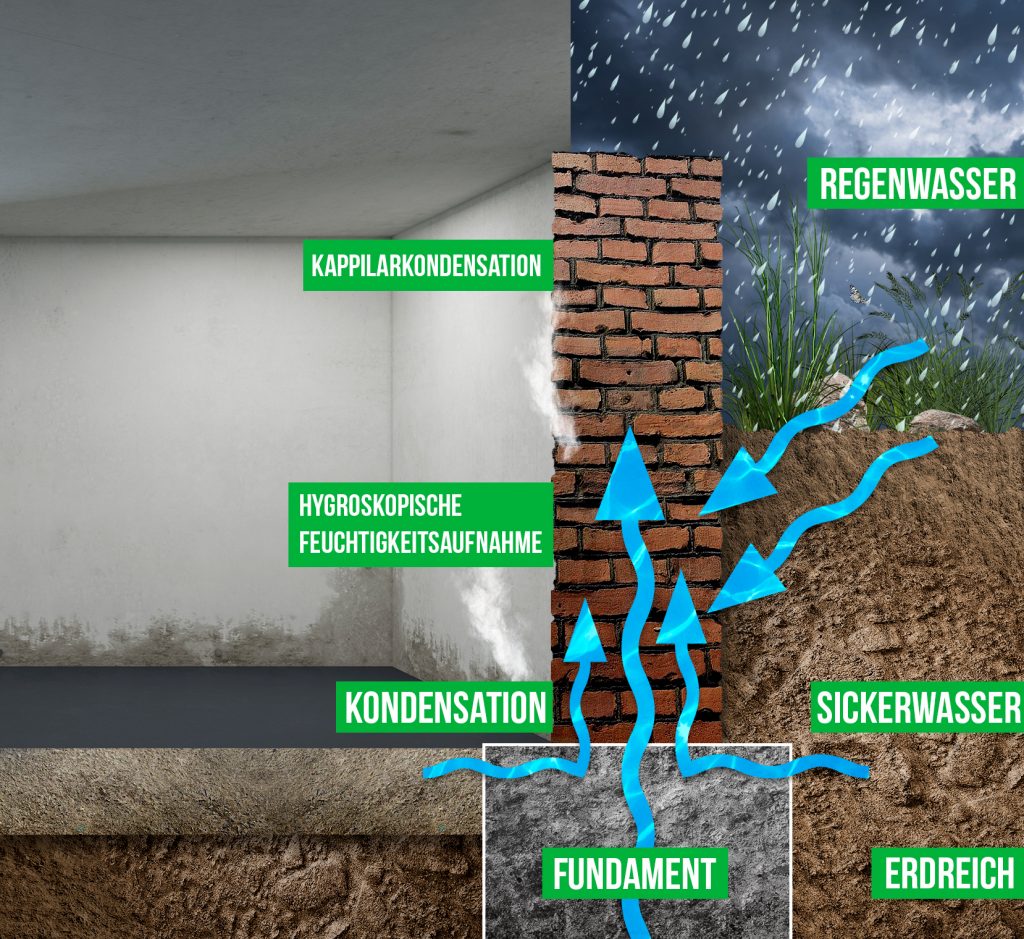

Ascending moisture

Moisture penetrates from the ground into a building structure and is transported upwards against gravity by the capillary effect. Cellar walls in particular cannot release the moisture absorbed in this way and remain permanently damp. In old buildings the waterproofing is often no longer functional due to age, or it is missing completely. The masonry often lies against the permanently damp ground without any protection. However, even in new buildings, the waterproofing is often faulty, making it imperative that improvements be made to prevent rising damp in the long term. Damp masonry loses its important heat-insulating properties and, in the worst case, can lead to the formation of mould, damage to the building structure and furnishings.

The consequences

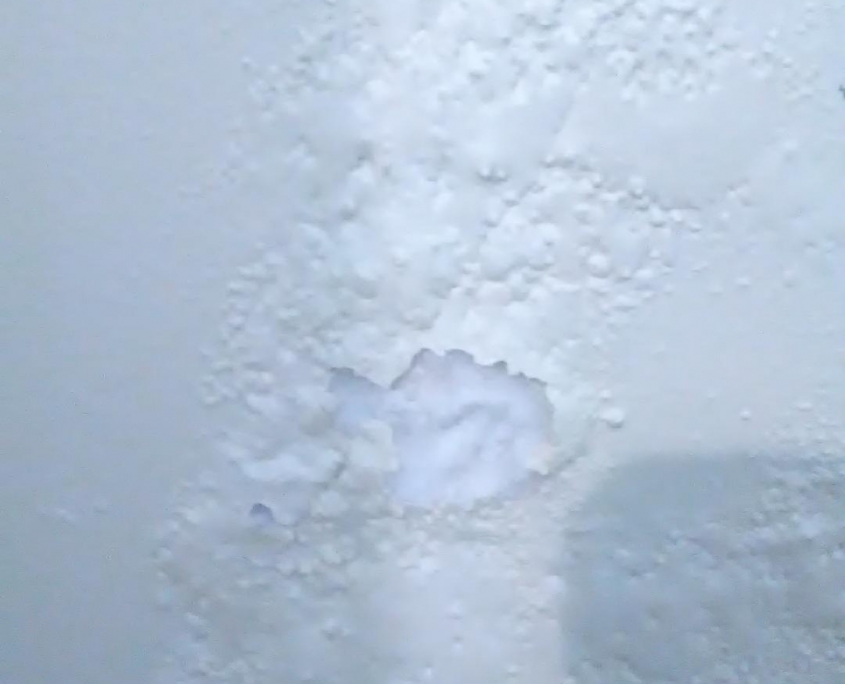

Chipping of plaster due to humidity

The solution

Hydrophobic horizontal barrier

To prevent wet walls or damp proof courses rising damp, a functioning horizontal barrier, also known as a cross-sectional seal, is essential. With the BKM.MANNESMANN system such a horizontal barrier can be retrofitted into the masonry. By means of an injection procedure from the inside, without the need for complex excavation. The horizontal barriers of BKM.MANNESMANN have an extremely long durability compared to other methods on the market and form a safe and durable barrier layer in masonry. A subsequent horizontal barrier can be installed in any type of masonry in which capillary moisture transport takes place.

The success

General information

In order to introduce subsequent barriers against moisture into a building component, injection via boreholes has proven itself for years. BKM.MANNESMANN has specialised in the production and processing of organic products, which are injected in this way and form a reliable barrier against rising damp or transverse moisture in mineral masonry. A polymer dissolved in highly pure paraffin oil provides a water-repellent coating in the pores of the building material.

Application

The material is injected into the component using low-pressure injection. For this purpose holes are drilled at an angle of about 45°. The drill holes are drilled into the wall at intervals of 12.5 to 25 cm, depending on the condition of the masonry and the selected product. A subsequent horizontal barrier is made in the lower part of the wall, but can also be placed above ground level, e.g. in a plinth, to protect the ground floor from rising damp.

How it works

The paraffin oil ensures that the material is distributed down to the finest cracks and pores. After injection into the infested masonry, it gradually evaporates completely again. At the end of the reaction time of approx. 3 weeks there is only a permanently water-repellent polymer film on the pore walls of the masonry, similar to a paint coat. The material is not water-soluble and even spreads in completely water-saturated masonry. Due to its composition and properties, it does not mix with the pore water present in the pores of the masonry. Due to the lower surface tension in relation to the existing water, the capillary pressure generated displaces the excess water from the capillaries.

Security

BKM injection products are produced under the strictest quality requirements and are constantly tested for consistent quality and product performance. For this purpose, BKM.MANNESMANN AG has defined its own product standards, which are valid throughout Europe, and guarantees compliance with them under the name BKM.MANNESMANN. So every customer can be sure to receive and use only the best quality. Certifications by independent material testing laboratories are an important part of the quality management at BKM and are available from various institutes.

Installation of a hydrophobic surface barrier

The cause

Transverse moisture penetration

Moisture can also enter the area above a horizontal barrier if there is damage to the vertical external waterproofing or if it is completely absent. The outside of the brickwork is constantly in contact with the damp soil and is thus soaked through by the capillary effect, which is revealed on the inside by discoloration, flaking plaster and a musty cellar smell. salts are responsible for the flaking of the plaster, which are washed out of the soil or the binding agents of the building materials and transported to the surface. In order to prevent such moisture penetration, an affected building component must be permanently protected against it.

The consequences

Transverse moisture penetration of a wall to the neighbouring house

The solution

Breathable Facade Protection

A barrier against rising damp is not sufficient in the case of transverse moisture penetration. BKM.MANNESMANN also offers a permanent solution for this: The surface barrier. Here the entire wall surface in contact with the ground is blocked against moisture penetration. In order to ensure such a “hydrophobicity” of the entire surface, holes are drilled like a chessboard and the material is thus brought into the wall. This is possible in any homogeneous masonry. Even in hollow bricks, as far as they have continuous mortar joints, this subsequent sealing can be realized. The surface barriers in the BKM.MANNESMANN system are also characterised by their long durability, which is a great advantage over other products.

The success

General information

In order to introduce subsequent barriers against moisture into a building component, injection via boreholes has proven itself for years. BKM.MANNESMANN has specialised in the production and processing of organic products, which are injected in this way and form a reliable barrier against rising damp or transverse moisture in mineral masonry. A polymer dissolved in highly pure paraffin oil provides a water-repellent coating in the pores of the building material.

Application

The proven borehole injection method is also used to create a subsequent surface barrier. The material is injected into the component using low-pressure injection. For this purpose, holes are drilled at an angle of about 45° and injection lances are used. Depending on the condition of the masonry, the drill holes are drilled into the wall at intervals of 12.5 to 25 cm, staggered like a chessboard. A subsequent barrier against transverse moisture penetration is created in the area of the wall that is in contact with the ground on the outside.

How it works

The paraffin oil ensures that the material is distributed down to the finest cracks and pores. After injection into the infested masonry, it gradually evaporates completely again. At the end of the reaction time of approx. 3 weeks there is only a permanently water-repellent polymer film on the pore walls of the masonry, similar to a paint coat. The material is not water-soluble and even spreads in completely water-saturated masonry. Due to its composition and properties, it does not mix with the pore water present in the pores of the masonry. Due to the lower surface tension in relation to the existing water, the capillary pressure generated displaces the excess water from the capillaries. Certifications by independent material testing laboratories are an important part of BKM’s quality management and are carried out and renewed at regular intervals.

Security

BKM injection products are produced under the strictest quality requirements and are constantly tested for consistent quality and product performance. For this purpose, BKM.MANNESMANN AG has defined its own product standards which are valid throughout Europe and guarantees their compliance with the name BKM.MANNESMANN. Thus, every customer can be sure to receive and use only the best quality. Certifications by independent material testing laboratories are an important part of the quality management at BKM and are carried out and renewed at regular intervals.